Hybrid generators deliver real benefits. It’s worth adding one to your fleet.

Each time we visit the American Rental Association (ARA) Show we’re looking out for the next best piece of equipment to add to our rental fleet. At last year’s show we picked up some new electric equipment – the latest models proving to be more productive than ever with longer battery life and really hitting that zero emissions demand in the market.

This year, we were laser-focused on adding hybrid generators to our fleet. Not only can they help lower emissions, but they can provide some pretty substantial fuel savings. And who doesn’t want to lower their fuel costs?

We’re pretty excited about providing customers with sustainable solutions like these – bridging the gap between those who are hesitant to try battery-only equipment and the ones that want to avoid diesel-burning generators running an inefficient load.

These hybrid generators are really hitting the sweet spot….and here’s why you should consider one to help power your next job site.

1.Continuous power….without all the noise and emissions

You may say a 25kw generator is nothing to get too excited about – it’s a pretty standard piece of equipment on most jobsites. But the Anacorp Energy Boss 25.15 kw generator is special and we’ve just added it to our rental fleet. It couples to a 15 kilowatt hour battery with a life cycle of 30 years or more at a 3kW average load. Just like a hybrid vehicle, the battery stores energy out of the generator.

We are excited about the benefits this piece of equipment is going to bring our customers. It’s what they’re asking for – quieter operations, longer maintenance intervals, emissions reduction and fuel savings (more on that later). Its compact design combines a 30kVA/24kW hybrid energy system that provides simultaneous three-phase and single-phase output voltages, capable of meeting a range of power requirements.

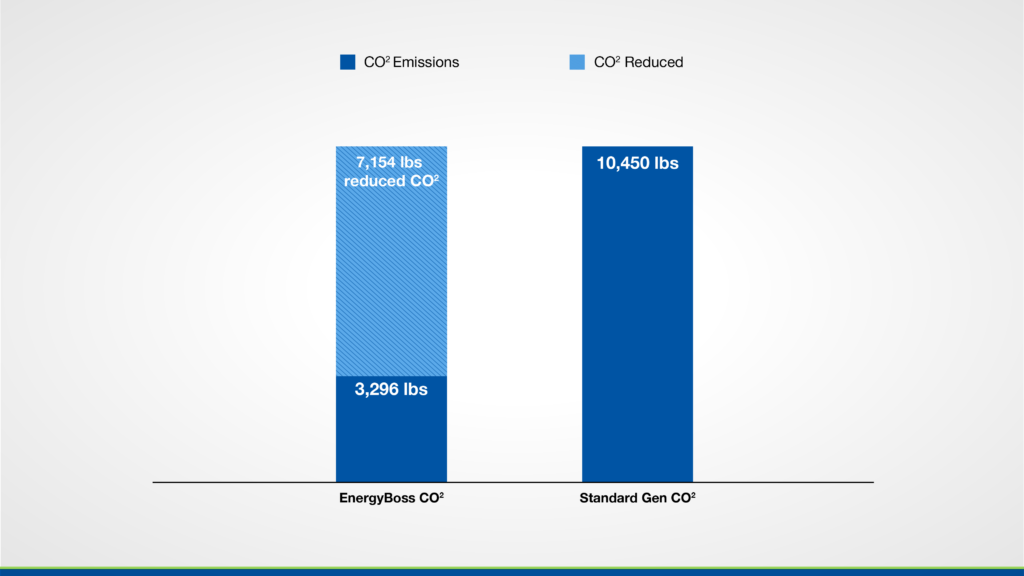

Early testing of the hybrid generator is revealing some impressive results. The chart below shows the carbon dioxide generated in one month by the Energy Boss generator vs. a standard generator. Over the period of one month, the hybrid generator emitted 68% less CO2 emissions!

2. Rest easy knowing your generator’s properly loaded.

As equipment providers, there’s no better feeling than a generator that’s properly loaded. Equipment that’s either over- or underutilized is all too common on the jobsite. When investing in a generator, as with any asset, it’s important to understand and implement the necessary requirements to keep operation and maintenance costs at a minimum. A decade ago, you might just push your equipment through to failure – resulting in carbon build-up in the unit and costly repairs for customers. New hybrid generators have sophisticated diagnostic systems…which means they can prevent failures before they become costly catastrophes.

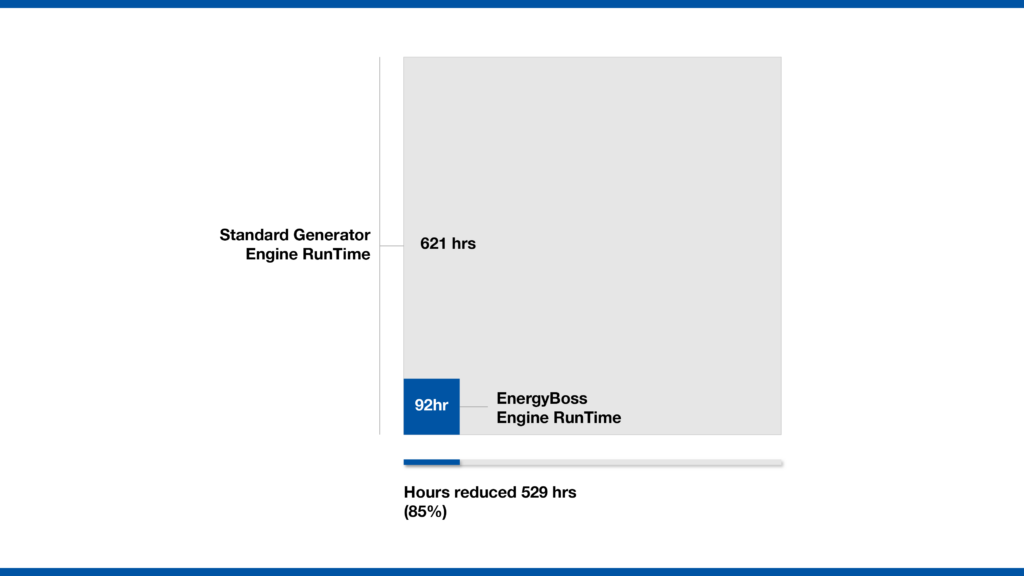

Traditional generators have to be sized for peak loads and must keep running even if loads are small. These new hybrid generators do the opposite. They operate in what we call the ‘Goldilocks zone’ – not too big, not too small….just right. And because they only run part of the time – they save on fuel and run time, reducing noise and extending service intervals.

3. Did someone mention fuel savings?

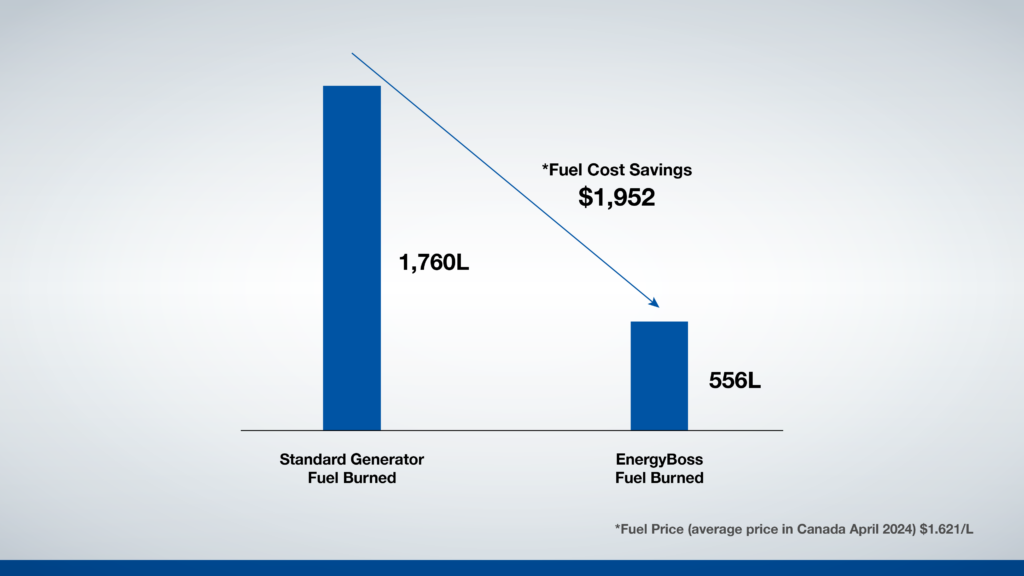

We decided to put these hybrid generators to the test. We looked at fuel consumption over a one month period and the results were impressive. The hybrid generator burned 556L (147 gal) vs. the standard generator which burned 1,760L (465 gal) of diesel…. That’s a difference of 1,204L (319 gal) and a 68% reduction in fuel costs.

It’s exciting to see these hybrid generators perform and we can’t wait to get these out to more customers. They’re designed to optimize diesel consumption – making them not just better for the environment but more cost effective too. If your hybrid generator isn’t running, you’re not burning fuel. And if you are using fuel, you’re doing it more efficiently.

Since the hybrid generator runs at maximum efficiency compared to a standard generator, engine hours were also reduced by 83%. This reduced demand on your unit also means it will experience less wear and tear over time. As a result, the equipment lasts longer with more time between maintenance intervals. Take your average trailer on the jobsite. It’s the first equipment to arrive on site and the last to leave and it’s often running around the clock. At 500 hour service intervals you’re going to need maintenance at least 7-8 times a year. With a hybrid model you’re cutting that number in half.

Underutilized generators are a thing of the past

We’re at an interesting moment in time. On one hand, we need to lower emissions to meet Tier 4 regulations. But on the other hand, the industry isn’t ready for fully electric jobsites. Despite all their benefits, cost is still an issue. A lot of contractors still have range anxiety with equipment that is battery-powered only. Then there’s the added barriers around power availability and lack of grid connection on most jobsites.

Stepping out of that comfort zone is a big deal. That’s why these hybrid generators are ticking all the boxes for us. Hybridization neatly bridges the gap between the two by cutting down on carbon emissions while offering quieter operations, longer maintenance intervals and fuel savings. And as we see more customers look to sustainable equipment as a way to wean themselves off fossil fuels we predict these hybrid generators to be a standard piece of equipment on jobsites in the near future. Any solution that can save customers money while increasing productivity and lowering emissions is a no-brainer. It’s why we invested in them…and think you should too.

Want to know more about the possibilities of hybrid generators? Contact our Pump & Power division to speak with a power specialist.

0 Comments